Design, molds and injection

Project development from day one

Welcome to Moldblade

Our highly experienced in-house engineering team can handle every stage of product development. Our highly experienced in-house engineering team can handle every stage of product development. We perform 3D scanning, 3D modelling and 3D printing. We are equipped with advanced machinery and CNC technology.

All precision injection moulds have been built with the following main equipment:

- 5 CNC

- 2 CNC rotary machines

- 6 EDM machines

- 2 precision wire cutting machines

- Two-dimensional (2D) and three-dimensional (3D) machine

In order to provide a global response locally, machinery has been distributed in 4 manufacturing plants.

Two-component, two-coloured, co-injection, thin-wall, IML (In-Mould Labelling) and gas-assisted injection.

We work for projects around the world. Read more about our sales network.

See Map

We manufacture injection molds and plastic products.

We develop reliable, high-precision complete projects across the globe.

Eco-friendly manufacturing and innovation as its objective.

We are firmly committed to sustainable and innovative projects. Sustainable manufacturing starts at home. That is why we have invested in low-consumption machinery, implementing ISO 14001. We use 100% renewable electricity and have combined solar panels with green roofing on our main factory building. We have partnered in and co‑financed prize‑winning sustainable projects. We also specialize in biomaterials and use a high proportion of recycled materials during manufacturing

Innovation is a driving force in our engineering department. We work closely with customers to develop innovative products, transforming what may begin as a mere idea into a lucrative invention. Moreover, an annual budget is allocated for innovating processes and for researching materials and additives.

We let our clients speak for us.

“Hemos desarrollado con Moldblade varios proyectos de entre 20 y 50 moldes a la vez partiendo de una preingeniería. Ellos se encargan de terminar de desarrollar los productos, prototipar y hacer ensayos con Moldflow y finalmente de fabricar toda la serie de moldes en un tiempo muy ajustado. El resultado ha sido siempre excepcional. Es un proveedor estratégico para nosotros.”

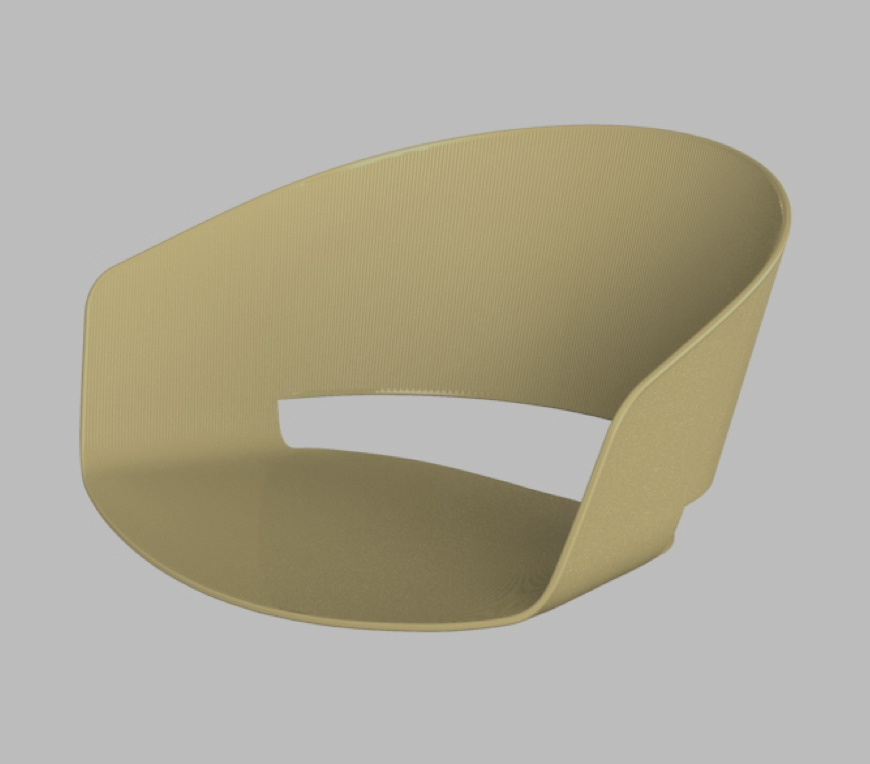

“Fabricamos sillas de alto standing de diseñadores top. Moldblade se encarga de que el diseño sea industrializable y esté optimizado. Después nos fabrica el molde e inyecta las piezas, dándonos la seguridad de que se encargan de todo el proceso.”

“Aunque contamos con nuestra propia matricería, a veces nos encontramos con proyectos que no podemos absorber. Moldblade nos ayuda a sacarlos adelante. En una ocasión desarrollamos un proyecto de 80 moldes, donde Moldblade se encargó del 70%, gracias a lo cual pudimos salir al mercado con la nueva línea de productos en los tiempos marcados.”