Dedication to innovation

We are committed to providing new solutions with our innovative projects, patents and materials.

Innovation

We have the capacity and vocation to develop innovative projects and technologies. That is why we set aside an ever-increasing budget for research.

Every year, we allocate funds for the industrial testing of new, technical and/or eco-friendly materials, aiming to provide new solutions and improvements in the sectors in which we work.

We work with our customers to develop patents in plastic. To do so, we support development from day one until achieving a functional result that is ready for the market.

We manufacture prototype molds for our own projects. This allows us to anticipate our customers’ needs and provide them with the best solutions.

We work on innovative refrigeration developments to meet the need for parts with high productivity demands.

Innovative projects

Discover some our most innovative projects

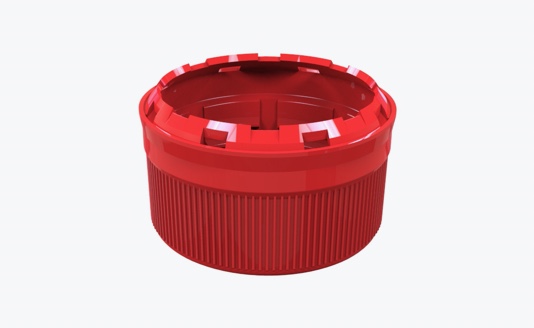

Compuesto Polipropileno

- PP copolímero

- Molde prototipo para tests

- Desarrollo de materiales para la industria bebidas

Nuestro partner Essentia (antes Propilco), fabricante multinacional de PP, colaboró con nosotros en el desarrollo de nuevas soluciones de PP que ofrecer a la industria en el ámbito de los tapones de bebida.

Gracias a la fabricación de moldes prototipo se pudo testar diferentes compuestos y optimizar el material, así como redefinir los requisitos de diseño en las nuevas tapas y tapones.

Tapa agrupación

- PLA+PVOH (biodegradable)

- Bicolor. Doble inyección

- Higiene garantizada mediante tapa abisagrada

En esta ocasión ayudamos a nuestro cliente a industrializar, optimizar profundamente el diseño y testar materiales para su producto innovador de agrupación de latas de bebidas.

Una solución higiénica, ecológica (biocompostable e hidrolusoluble) y práctica que llega para sustituir a los actuales sistemas de agrupación en cartón o PVC.

Tapón abatible

- PLA+PVOH (biocompostable)

- Tapa unida a la botella mediante precinto y bisagra

- Desarrollo inicial con moldes prototipo

Yendo por delante del mercado, presentamos esta solución antes de que fuera obligatorio. Moldblade aportó todo el desarrollo, análisis, testado y pruebas de moldes.

Criaderos de algas

- HDPE

- Diseño estructural articulado

- Sobreinyección metálica

La cría de algas sistematizada es una solución mucho más económica para este tipo de vegetal tan apreciado en alimentación, cosmética y otras muchas aplicaciones.

Moldblade colaboró en el desarrollo de este proyecto desde su concepción, donde una mayoría de piezas plásticas unidas a varias piezas metálicas se unen para ofrecer un sistema totalmente nuevo y rompedor.

Do you have a new idea?

Let’s make it a reality!

Our team will conduct a feasibility study of your project at its early stages, with no commitment from you.