Plastic engineering

We develop lucrative, sustainable and innovative projects worldwide.

Projects from its inception

Safety and guaranteed results

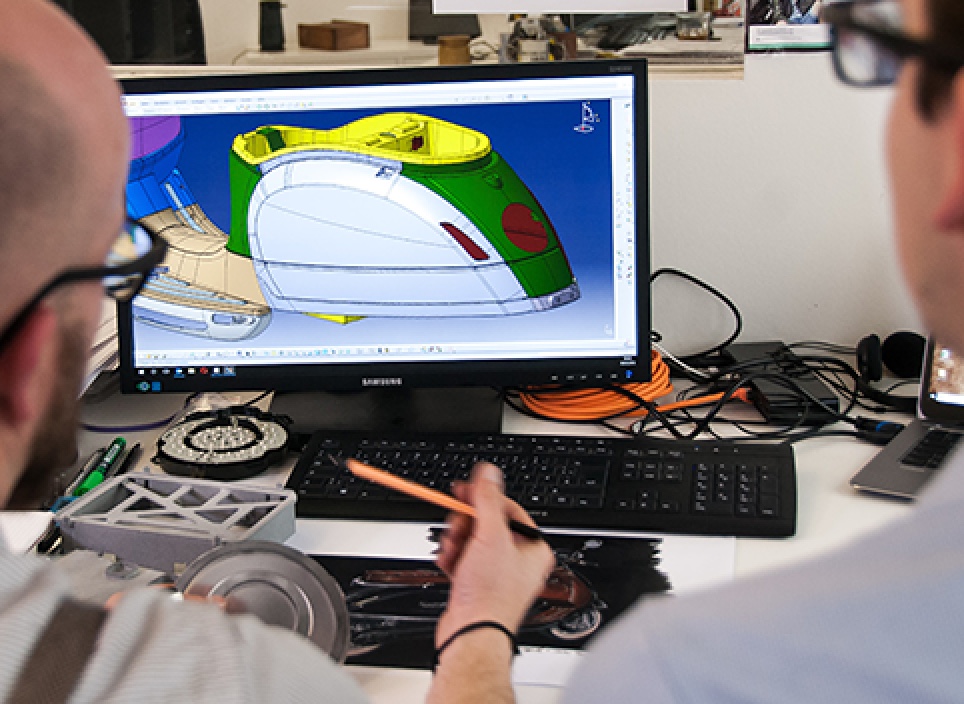

Our commitment to providing high-quality plastics engineering services is what sets Moldblade apart. Our approach is multidisciplinary, as it requires extensive knowledge of different materials and their behavior, mechanical strength calculation, plastic flow calculation, heat transmission, mold mechanics, as well as specific expertise in each industry sector.

Our services involve the entire developmental process of parts. This way, we ensure the success of every project, because the outcome is always optimal when a single company draws on all its expertise to handle every step of the process: engineering, mold manufacturing and injection.

New product

Industrial design through a comprehensive development process

- Briefing analysis

- Market research

- Conceptualisation and concept sketching

- 3D modelling of formal proposals

- Structural calculation

Product restyling

Improvements and optimisations of weight, resistance, cost and aesthetics.

- Analysis of injection defects

- Functional aesthetic restyling

- Thickness optimisation

- Functional prototype

Layout

Our goal is to turn ideas into products that can be mass produced.

- 3D Scanning

- Error detection

- Aesthetic and functional restyling

Development

This process involves perfecting the product’s components and mechanical parts.

- Structural calculation

- Moldflow

Prototype

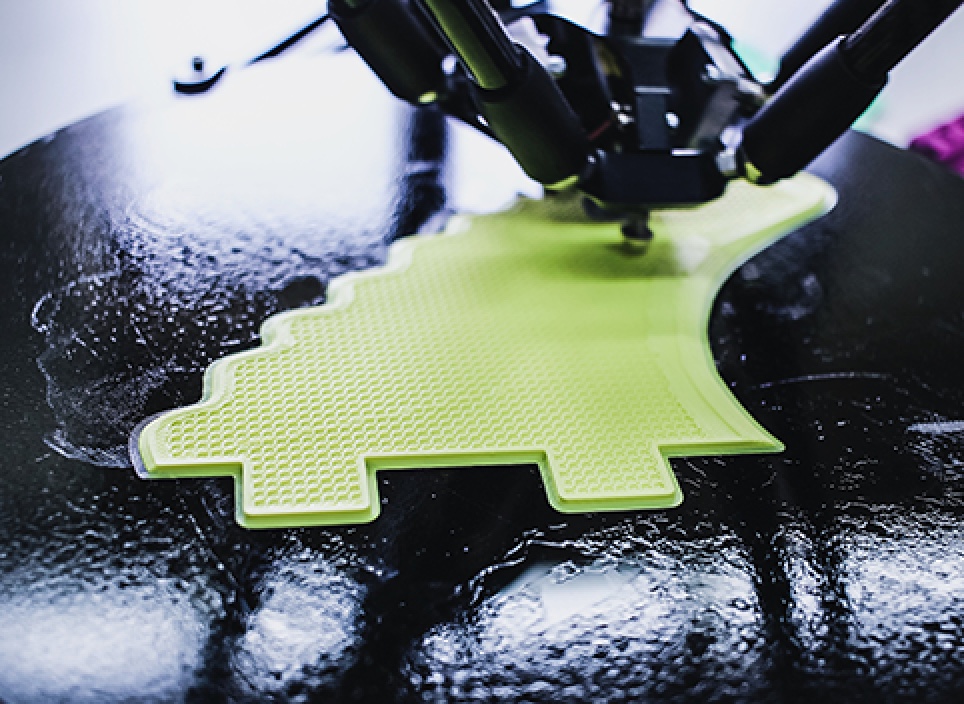

Prototyping is a value-added service that we offer as a default option, at no cost to the client.

- 1:1 scale ABS machining

- 3D printing, stereo

Projects

We create molds and plastic injection parts for a wide range of sectors. Our extensive experience in providing products that are tailored to the specific needs of each customer qualifies us to offer a highly reliable comprehensive service