7 advantages of injection moulded parts production

By Julio Serrano Mira

Manufacturing Process Engineering Area.

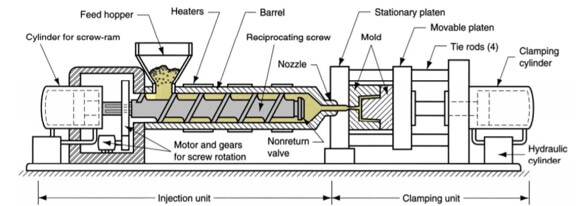

Injection moulding of plastics is the most widely used method for the manufacture of thermoplastic parts, approximately 60% of plastic processing machines are injection moulding machines.

They can be used to produce parts weighing from a few milligrams to almost 100 kg. Injection moulding can produce intricate and complex shapes, the limitation is the ability to produce a mould whose cavity has the same shape as the part, and the mould must allow the part to be ejected. In applications requiring a high production rate and good dimensional control, this process is the most common for thermoplastic polymer forming.

Moldblade

From a design point of view, one of the main improvements provided by plastic injection moulding is the possibility of incorporating several functions into a single part, so that the number of parts and assembly time can be reduced.

We can say that the most relevant advantages of the manufacture of plastic parts by injection moulding are the following:

- Manufacturing speed. The cooling speed of thermoplastics is almost immediate and consequently the production cycles are short, between 10 and 30 seconds.

- It allows you to obtain the finished product in a single step.

- In general, no finishing processes on the part are necessary.

- It is a fully automatable process.

- The manufacturing conditions are easily reproducible.

- Very complicated parts can be obtained.

- The finished parts are of high quality.

It is important to note that polymers have high coefficients of thermal expansion, and significant shrinkage of the plastic in the mould occurs during cooling. After injection into the mould, some thermoplastics experience shrinkage of close to 10% in volume. Therefore, the mould cavity dimensions must be larger than those specified on the part in order to compensate for this shrinkage.

From Moldblade we offer a wide range of injection moulded plastic parts such as housings, containers, lids, automotive parts, toys, household appliance parts, tools, waste bins, plastic shopping trolleys, plastic cutlery and many other items of our daily life.

13 November, 2020

Siguiente artículo:

Moldblade y Tragsa. Proyecto conjunto para modernizar el control de riego en la zona del Zújar.